Your Strategic Fire Safety Partner

From specification to installation, Kinde Fire delivers export-quality firefighting equipment with complete engineering support. ISO 9001:2015 certified, trusted in 26+ countries worldwide.

Fire Safety Equipment Solutions

From water monitors to hose reels, we manufacture complete fire protection systems meeting IS, NFPA and international standards

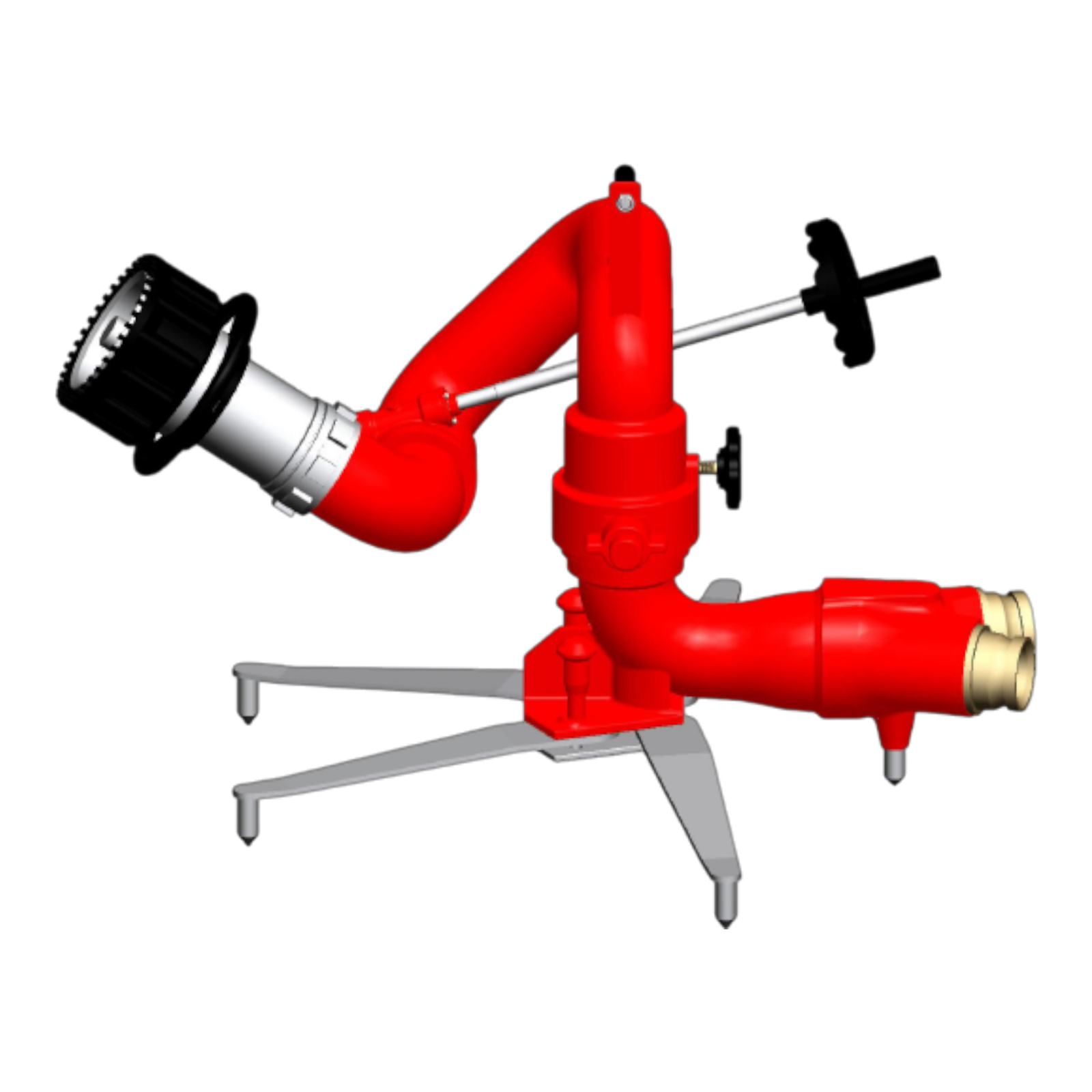

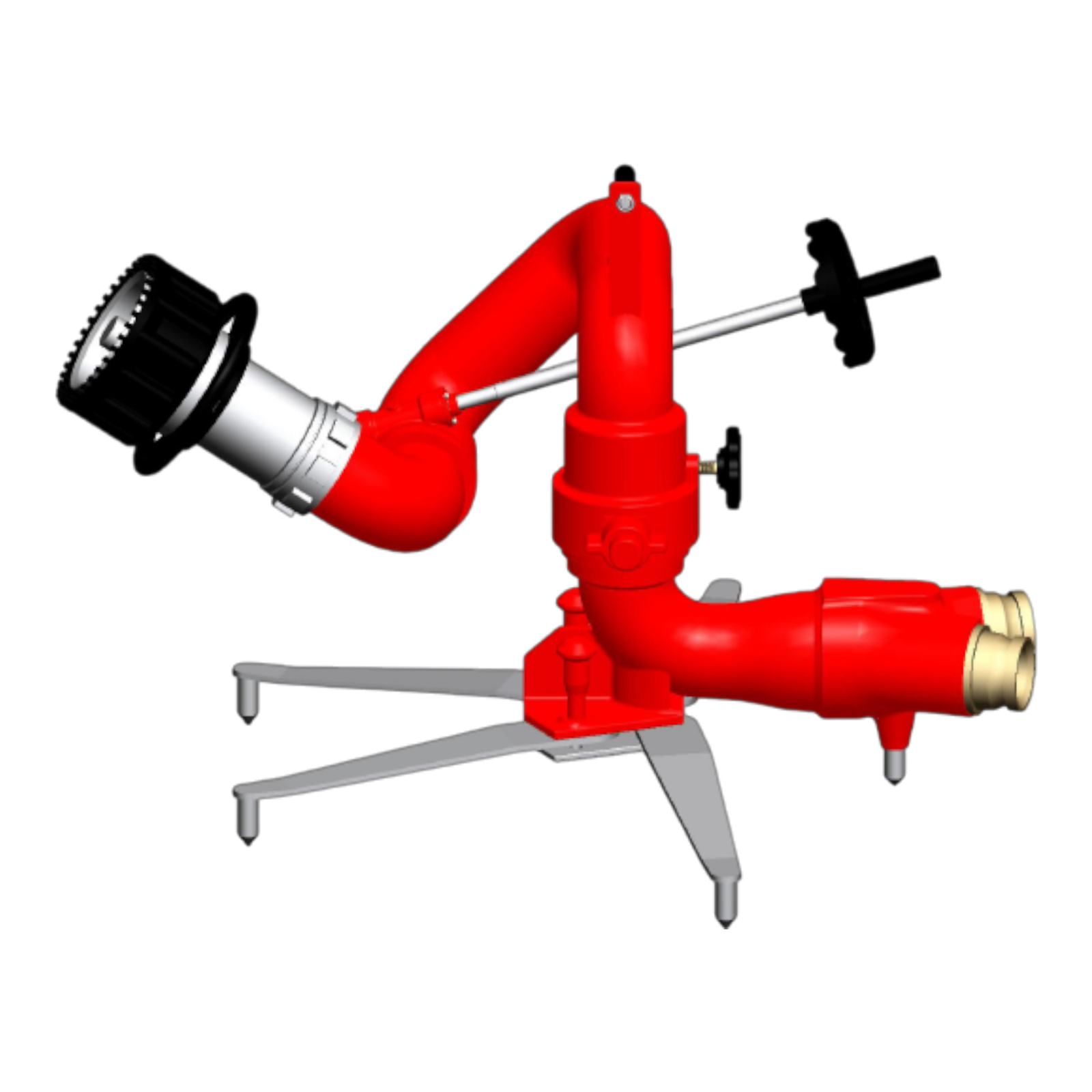

Super Solid Jet Water Monitor

High-pressure water monitors with 53m throw range. 360° rotation, -45° to +80° elevation. Perfect for industrial facilities and refineries.

Fire Hose Pipes Type I, II, III

IS 636 certified fire hose pipes. Standard rubber-lined to chemical-resistant variants for all industrial applications. UL & MMD Approved Hose Pipes

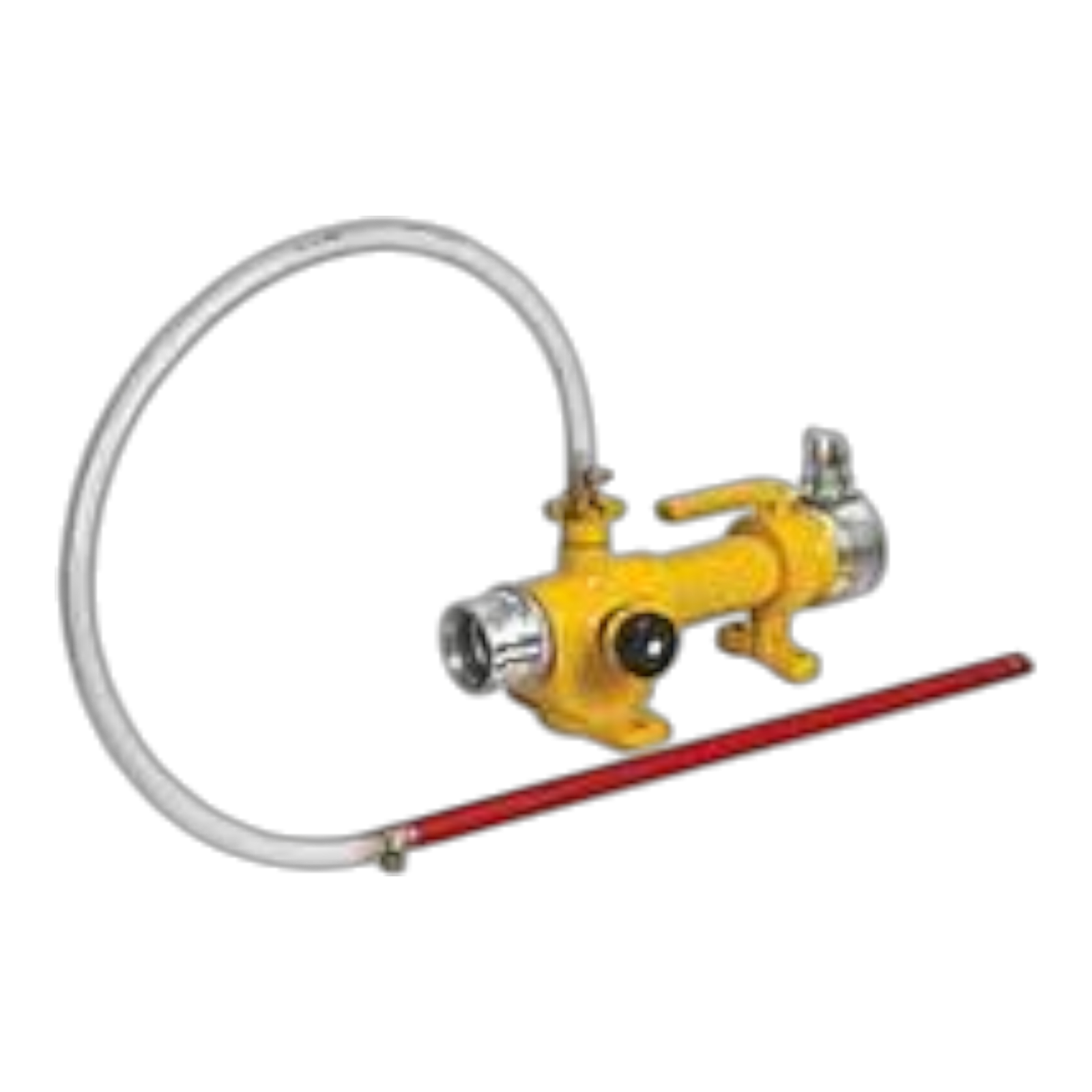

Fire Fighting Nozzles

Handline Nozzles are used to directly attached on the hose pipe to guide the flow and throw of the water and foam on the fire. This are light weight easy to Handle Nozzles in India.

Fire Hose Box Cabinet

Single/double door fire cabinets in FRP / MS / SS304 / SS 316. Houses hose reel, extinguisher, and safety accessories.

Fire Hydrant Stand Post

Single, double and quad-headed hydrant systems. Underground/overground with pumper connection options.

Mobile Foam Trolley Unit

Trolley mounted foam units for petrochemical, refinery and airport applications. FRP and SS tank options.

Explore Our Fire Safety Range

Hover to pause • Click to view details

Why Global Leaders Choose Kinde Fire

Beyond manufacturing — we deliver complete fire safety partnerships

4-Hour Quote Response

Detailed technical quotations with specifications and drawings within 4 hours via WhatsApp or email.

ISO 9001:2015 Certified

Rigorous quality management ensures every product meets international standards with complete traceability.

26+ Countries Worldwide

From UAE refineries to Kenyan facilities, our equipment protects installations across 6 continents.

Complete Documentation

MTC, test reports, dimensional drawings, and operation manuals with every shipment.

Custom Engineering

Need special materials or pressure ratings? We customize products to your exact project requirements.

25–40% Cost Savings

Direct manufacturer pricing delivers exceptional value while maintaining premium quality standards.

Start With a Free Technical Consultation

Before investing in fire equipment, ensure you're specifying the right solution. Our engineers will review your requirements and provide recommendations at no cost.

How We Work With You

A proven three-step approach from consultation to delivery

Consult

We understand your facility requirements, compliance standards and protection objectives to define the right solution.

Engineer

Our technical team specifies equipment with precise calculations for flow rates, pressure ratings and system integration.

Deliver

We manufacture to international standards with complete testing, documentation and export-ready packaging.