FIRE FIGHTING EQUIPMENT MANUFACTURER

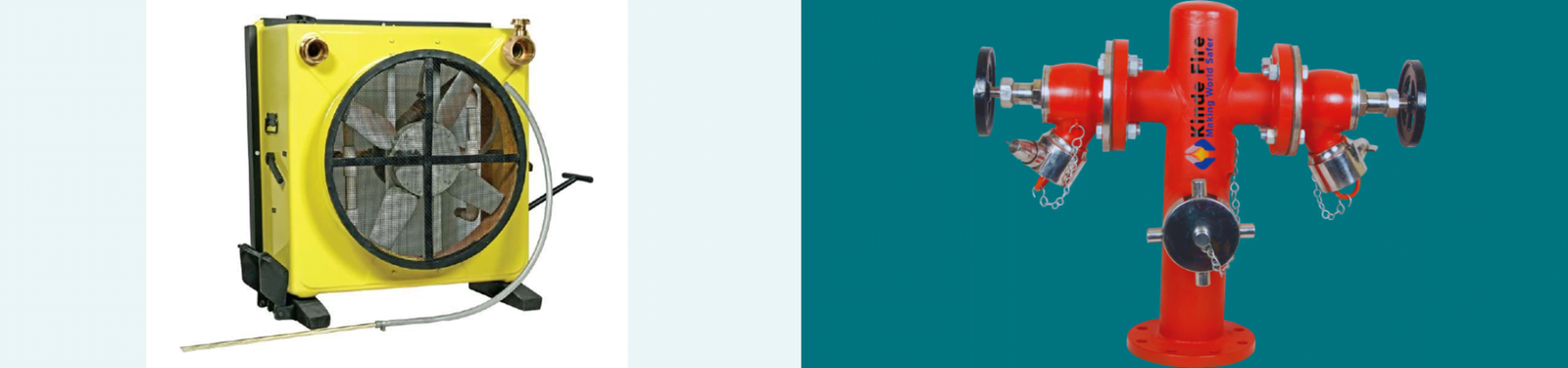

Kinde Fire, a brand of iThing Mechatronics LLP, stands as a premier manufacturer of fire fighting and safety equipment in India. We specialize in a comprehensive range of products designed to ensure maximum safety and reliability. Our offerings include:

- Fire Extinguisher Boxes

- Fire Hose Cabinets

- Fire Hose Reel Drum Cabinets

- Mobile Foam Trolley Units

- Dry Riser Fittings

- Portable Foam Equipment

- Fixed Foam Equipment

- Stand Post Type Hydrants

- Customized Fire Fighting Solutions

When it comes to fire safety, specialized equipment plays a critical role in ensuring a quick and effective response to emergencies. In this guide, we’ll explore five essential components of fire fighting systems: Fire Cabinets, Dry Riser Fittings, Foam Making Equipment, Mobile Foam Units, and Handline Nozzles. Understanding these components is vital for both fire safety professionals and organizations looking to enhance their fire response capabilities.

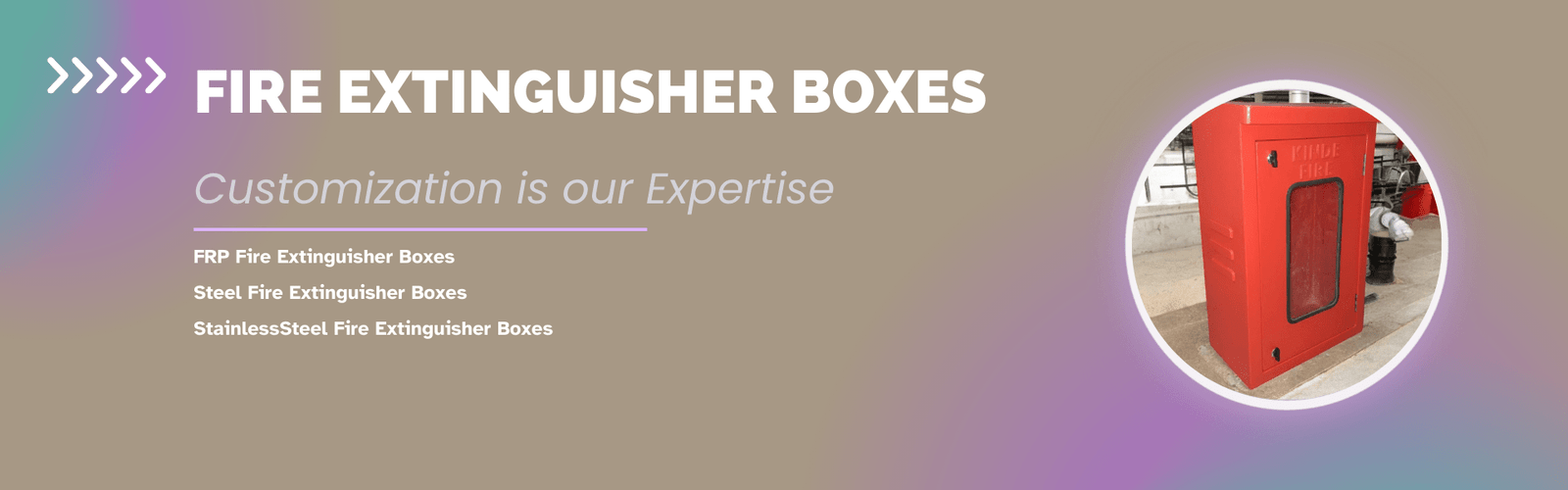

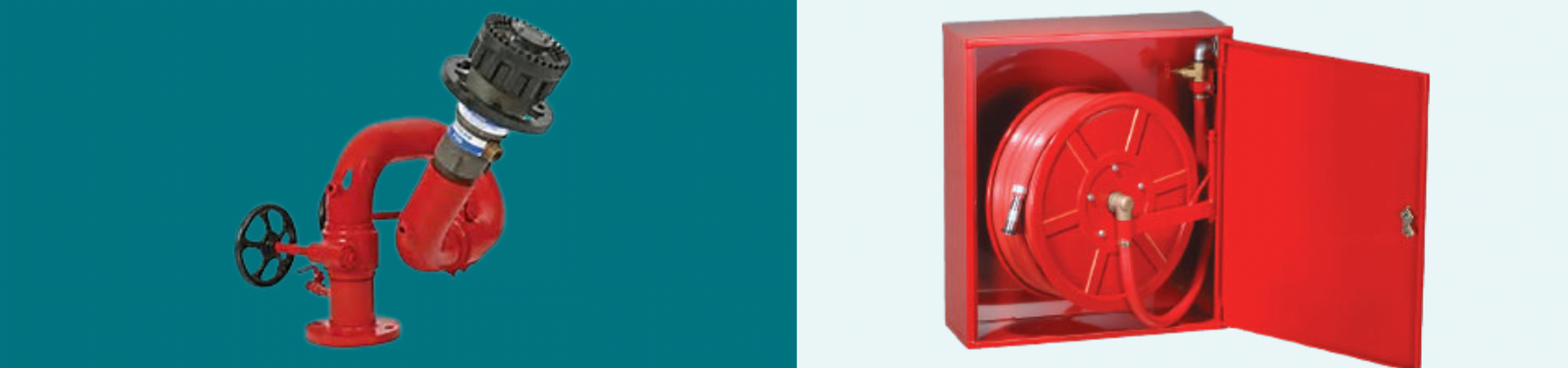

1. Fire Cabinets

Fire cabinets are crucial for housing fire safety equipment, protecting them from damage, and ensuring quick access during emergencies. Typically installed in commercial, industrial, and residential buildings, fire cabinets come in various types to store fire hoses, extinguishers, and other firefighting tools. They help keep the equipment safe from vandalism, dust, and environmental factors.

Key Features:

- Durability: Fire cabinets are built with robust materials like stainless steel or powder-coated metal to withstand harsh environments.

- Easy Access: Designed with quick-opening mechanisms for rapid response.

- Customization: Available in various sizes and configurations, fire cabinets can be tailored to store different types of equipment.

Primary Uses:

Fire cabinets are commonly found in areas like:

- High-rise buildings

- Factories and industrial sites

- Warehouses

- Hospitals and shopping malls

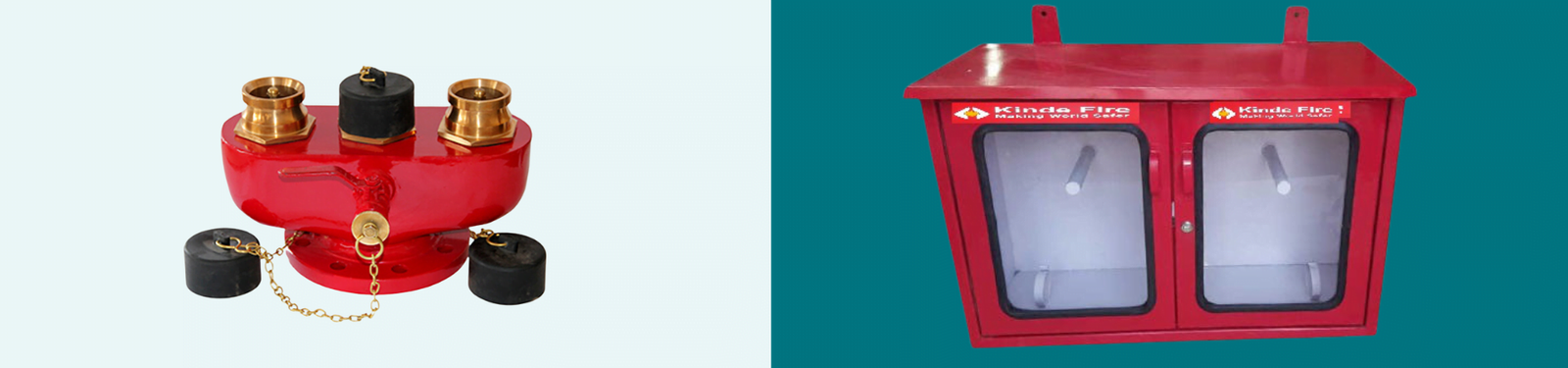

2. Dry Riser Fittings

Dry riser fittings are essential components in buildings designed to supply water to different floors during a fire. A dry riser system is a network of pipes that remain empty under normal conditions but can be quickly filled with water from external sources, such as fire trucks, when needed. These fittings include inlets, outlets, and valves that connect to fire hoses.

Types of Dry Riser Fittings:

- Inlet Breechings: Allow firefighters to connect external water supplies to the dry riser.

- Landing Valves: Installed on each floor, providing connection points for fire hoses.

- Blank Caps and Chains: Protect the inlets from damage and debris when not in use.

Importance:

- Water Supply: Ensures rapid water availability at various levels of the building during a fire.

- Compliance: Essential for meeting fire safety regulations in multi-story buildings.

3. Foam Making Equipment

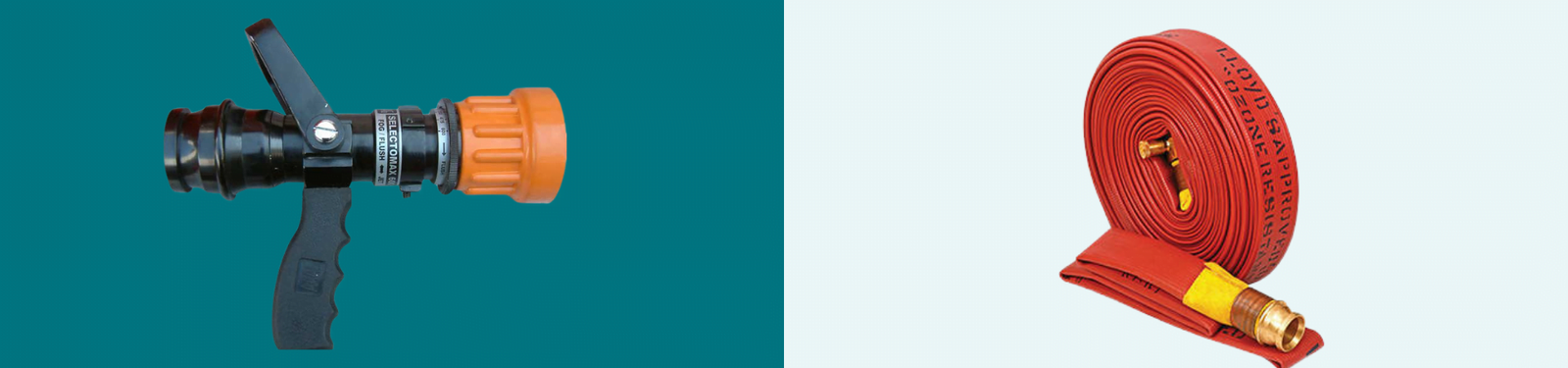

Foam making equipment plays a vital role in extinguishing flammable liquid fires by producing foam that suffocates the fire and prevents re-ignition. Foam is particularly useful for combating fires involving oil, gasoline, and other hazardous materials. Foam-making equipment typically includes foam generators, proportioners, and nozzles that mix foam concentrate with water to generate foam.

Types of Foam Making Equipment:

- Inline Foam Inductors: Used to inject foam concentrate into the water supply at the correct ratio.

- Foam Generators: Produce high-expansion foam for larger-scale fire suppression.

- Foam Proportioners: Ensure precise mixing of foam concentrate and water.

Applications:

- Oil and Gas Industry: For fires involving flammable liquids and chemicals.

- Airports: For handling aircraft fuel fires.

- Marine and Offshore Platforms: For emergencies involving fuel leaks and fires on ships or platforms.

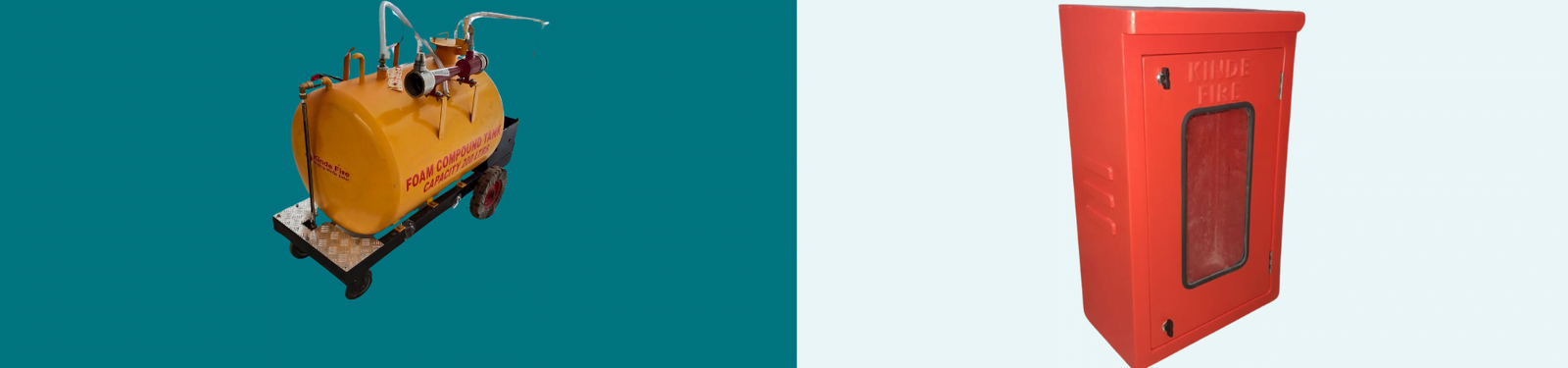

4. Mobile Foam Units

Mobile foam units are versatile and portable fire fighting systems that can be quickly transported to the scene of a fire. They are designed to provide large volumes of foam to combat fires involving flammable liquids and gases. These units come equipped with foam tanks, hose reels, and nozzles, allowing firefighters to deploy foam rapidly in emergency situations.

Key Components:

- Foam Tank: Holds foam concentrate, usually with a capacity of 100-150 liters.

- Foam Inductor and Hose Reel: Allows for the precise application of foam to the fire site.

- Trolley System: Ensures mobility and easy transport to different locations.

Benefits:

- Rapid Deployment: Can be quickly mobilized to contain fires in critical situations.

- High Efficiency: Capable of delivering a large volume of foam to control fires swiftly.

- Portable: Easily maneuvered by one or two operators, making it ideal for large facilities.

Common Uses:

- Refineries and petrochemical plants

- Aircraft hangars

- Oil storage facilities

- Warehouses with hazardous materials