Ultimate Guide to Train Your Team with FRP Mobile Foam Units

Essential Training Modules for Your Team

Training on a Mobile Foam Units is crucial for ensuring your team knows how to use this life-saving equipment effectively. Providing comprehensive training modules on Mobile Foam Units can make all the difference when it comes to preparedness and response times during emergencies. Here, we’ll explore the key modules your team needs to master for optimal performance with the FRP Mobile Foam Units.

Understanding the Basics of Training on Mobile Foam Units:

First, your team needs to understand what the FRP Mobile Foam Units is and why it’s important. This might seem basic, but it’s the foundation for everything else. Start with an introduction to the equipment, including its components and primary functions. You want your team to feel comfortable with the unit, not intimidated. Knowing how the foam cart works and what each part does will build confidence and competence.

Make sure you cover the different types of foam agents and their specific uses. Your team should know which foam agent to use for different types of fires. This knowledge can prevent mishaps and ensure the foam unit is used effectively. Consider a hands-on demonstration where team members can see and touch the components. This tactile experience can reinforce their learning and make the information stick.

Operating the Mobile Foam Units:

Now that your team understands the basics, it’s time to dive into operating the foam unit. Training on Mobile Foam Units should include detailed instructions on how to start, operate, and stop the unit safely. Break down each step into easy-to-follow instructions. You want this to be second nature for your team.

Begin with the startup process. Show your team how to properly set up the unit, ensuring all connections are secure. Explain the importance of checking for leaks or damages before use. Next, walk them through the operation of the unit. This includes how to control the foam spray and adjust the pressure settings. Make sure everyone gets a chance to practice these steps under supervision.

Key Takeaway

Remember these important insights as you continue reading.

Emphasize the importance of regular maintenance during operation. Your team should know how to perform quick checks and basic maintenance while the unit is in use. This can prevent minor issues from turning into major problems. Finish with the shutdown process, ensuring your team knows how to safely power down the unit and prepare it for storage. Want to learn more on How to Operate Mobile Foam Units.

Safety Protocols

Safety should always be a top priority when working with an FRP Mobile Foam Units. Include a comprehensive module on safety protocols to ensure your team knows how to protect themselves and others. Start by outlining the personal protective equipment (PPE) required when operating the foam unit. Helmets, gloves, and protective clothing should be non-negotiable.

Discuss common hazards associated with using the Mobile foam units. These might include handling chemicals, managing high-pressure hoses, and navigating slippery surfaces. Your team should know how to identify and mitigate these risks. Conduct drills that simulate real-life scenarios to give your team hands-on experience in a controlled environment. This can help them stay calm and effective during an actual emergency.

Additionally, cover emergency procedures in case something goes wrong. Your team should know how to shut down the unit quickly and evacuate the area if necessary. Review these procedures regularly to keep them fresh in everyone’s minds. Remember, a well-trained team is a safe team.

Troubleshooting and Maintenance

Lastly, include a module on troubleshooting and maintenance. Even the best equipment can experience issues, so your team needs to know how to identify and fix common problems. Start by teaching them how to conduct regular inspections. They should know what to look for in terms of wear and tear or potential malfunctions.

Walk them through common issues they might encounter, such as low foam output or mobility problems. Provide step-by-step instructions for diagnosing and fixing these problems. For instance, if the foam output is low, your team should know to check the foam concentrate level, inspect the hoses for blockages, and verify the pressure settings.

Key Takeaway

Remember these important insights as you continue reading.

Maintenance training should also cover routine cleaning and refilling of foam agents. Show your team how to clean the foam tank and hoses properly to prevent blockages and ensure smooth operation. Teach them the correct procedure for refilling foam agents, including checking expiration dates and avoiding overfilling. Want to learn more details about Maintenance of Mobile Foam units?

Encourage your team to keep a maintenance log. This helps track when inspections, cleanings, and refills were last done and identifies any recurring issues. A well-maintained foam unit is more reliable and effective during emergencies.

Training on Mobile Foam Units is essential for your team’s safety and efficiency. By covering the basics, operation, safety protocols, and maintenance, you ensure your team is well-prepared to handle emergencies. Regular training sessions and hands-on practice can make a significant difference in your team’s confidence and competence. Remember, the better trained your team is, the more effectively they can use the FRP Mobile Foam Units when it matters most. So, invest time in comprehensive training modules and watch your team’s skills and readiness soar.

Hands-On Practice Sessions: Bringing Training to Life

Training on a Mobile Foam Units is crucial, but nothing beats hands-on practice sessions to cement the learning experience. When your team gets their hands dirty, they truly understand how to operate and maintain the FRP Mobile Foam Units. These sessions should be interactive, engaging, and as close to real-life scenarios as possible. Let’s dive into how you can make the most out of hands-on practice sessions.

Simulate Real Emergencies

Start by simulating real emergencies to give your team a feel of actual firefighting scenarios. Create mock situations where they must use the FRP Mobile Foam Units under pressure. This not only tests their skills but also builds their confidence. You can use controlled fires, timed drills, and obstacle courses to make the sessions challenging and realistic. For further details on technical training on Fire Training click here.

Key Takeaway

Remember these important insights as you continue reading.

For instance, set up a scenario where they need to extinguish a controlled fire within a set time. Include obstacles like navigating through a cluttered area or dealing with a simulated injured person. This helps them practice multitasking and quick decision-making. The goal is to mimic the chaos of real emergencies while ensuring everyone learns safely.

Encourage teamwork during these drills. Split your team into groups and have them work together to solve problems. This fosters collaboration and communication, essential skills in emergency situations. Plus, it’s a great way to build camaraderie and trust among team members.

Get Familiar with Equipment

Next, ensure your team gets hands-on experience with all parts of the Mobile Foam Unit. This involves more than just operating the unit; they need to be comfortable with assembling, disassembling, and troubleshooting it. Start with basic tasks like connecting hoses, checking foam levels, and operating the spray mechanism.

Encourage them to take turns handling different components. One session could focus on setting up the unit from scratch, while another might involve performing a routine maintenance check. Rotate these tasks regularly so everyone gets a chance to practice each aspect.

You can also include sessions on identifying and fixing common issues. For example, create a scenario where the foam output is low and have them troubleshoot the problem. This might involve checking the foam concentrate level, inspecting hoses for blockages, and adjusting pressure settings. Hands-on troubleshooting builds problem-solving skills and ensures your team can handle unexpected issues confidently.

Regular Review and Feedback

Hands-on practice sessions are more effective when followed by regular review and feedback. After each session, gather your team for a debriefing. Discuss what went well and what could be improved. Encourage everyone to share their experiences and insights.

Provide constructive feedback and highlight areas for improvement. For example, if someone struggled with hose management, offer tips on better techniques. If a team did exceptionally well, acknowledge their efforts. Positive reinforcement boosts morale and motivates everyone to keep improving.

Key Takeaway

Remember these important insights as you continue reading.

Use these debrief sessions to review safety protocols and correct any mistakes. If someone forgot to wear their protective gear or missed a step in the procedure, address it immediately. Safety is paramount, and reinforcing these protocols ensures everyone is aware and vigilant.

Consider recording the sessions for later review. Watching themselves in action can help team members spot their own mistakes and understand your feedback better. It’s a powerful tool for self-improvement and accountability.

Make it Fun and Engaging

Training doesn’t have to be all serious business. Adding a fun element to your hands-on practice sessions can enhance learning and keep your team engaged. Organize friendly competitions to test their skills and speed. For instance, see who can set up the unit the fastest or who can extinguish a mock fire most efficiently.

Create team challenges where groups compete to solve problems or complete tasks. This not only makes the training enjoyable but also encourages teamwork and creative thinking. You can even offer small rewards for the winning team to boost motivation.

Incorporate different learning styles into your sessions. Some people learn best through doing, while others benefit from visual aids or verbal instructions. Use diagrams, videos, and demonstrations to cater to all learning preferences. This ensures everyone gets the most out of the training.

Continuous Improvement

Training on a Mobile Foam Unit is not a one-time event. Continuous practice and improvement are key to maintaining a high level of readiness. Schedule regular hands-on practice sessions to keep skills sharp and updated. The more your team practices, the more confident and competent they will become.

Stay updated with the latest techniques and advancements in firefighting technology. Incorporate new methods and equipment into your training sessions. This keeps your team at the forefront of best practices and enhances their capability to handle emergencies.

Key Takeaway

Remember these important insights as you continue reading.

Encourage your team to seek additional training and certifications. There are many specialized courses available that can deepen their knowledge and expertise. Investing in ongoing education shows your commitment to their professional growth and the overall safety of your operations.

Safety Protocols and Procedures for Mobile Foam Unit: Keeping Your Team Safe:

When it comes to training on a Mobile Foam Unit, safety is paramount. Proper safety protocols and procedures ensure your team can handle emergencies effectively while minimizing risks. Let’s dive into the essential safety practices you should incorporate into your training sessions.

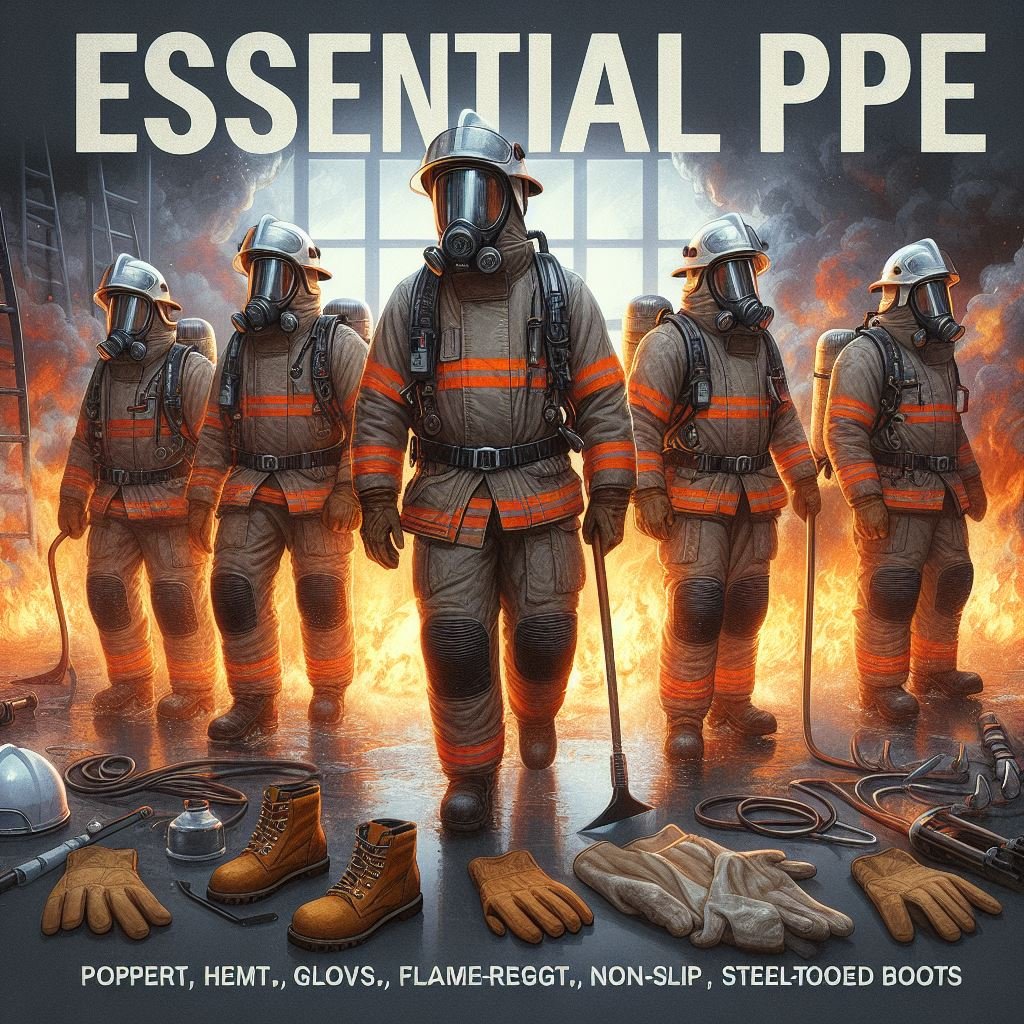

Personal Protective Equipment (PPE) Essentials:

First and foremost, equip your team with the right personal protective equipment (PPE). PPE is crucial for protecting against potential hazards during operation. Make sure everyone understands the importance of wearing PPE and knows how to use it correctly.

Common PPE for Operating a Mobile Foam Unit Includes:

- 1 Helmets: Protects against head injuries from falling debris or impacts.

- 2 Gloves: Shields hands from chemicals, heat, and abrasions.

- 3 Protective Clothing: Flame-resistant suits or jackets to protect against heat and fire.

- 4 Safety Goggles: Protects eyes from foam chemicals and debris.

- 5 Boots: Non-slip, steel-toed boots for foot protection and stability.

Conduct Regular Safety Checks

Before using the Mobile Foam Unit, conduct thorough safety checks. Inspect the equipment for any signs of damage or wear. Check hoses, connections, and foam levels to ensure everything is in working order. Address any issues immediately to prevent accidents during operation.

Safe Handling of Foam Agents

Foam agents used in firefighting can be hazardous if not handled properly. Train your team on the safe handling, storage, and disposal of these agents. Ensure they understand the potential risks and know how to mitigate them.

Key Safety Tips for Handling Foam Agents:

- 1 Use Proper Containers: Store foam agents in approved, labeled containers.

- 2 Avoid Skin Contact: Use gloves and protective clothing to avoid direct contact.

- 3 Ventilation: Work in well-ventilated areas to avoid inhaling fumes.

- 4 Spill Management: Have spill containment kits available and train your team on how to use them.

Emergency Shutdown Procedures of Mobile Foam Unit

Equip your team with the knowledge of emergency shutdown procedures. In the event of a malfunction or dangerous situation, they should know how to quickly and safely power down the unit.

Key Takeaway

Remember these important insights as you continue reading.

Steps for Emergency Shutdown:

- 1 Turn Off the Power: Immediately shut off the power source to the unit.

- 2 Disconnect Hoses: Safely disconnect hoses to prevent leaks.

- 3 Evacuate the Area: Ensure everyone moves to a safe distance.

- 4 Notify Supervisors: Report the incident to a supervisor or emergency services.

Regular Safety Drills

Incorporate regular safety drills into your training program. These drills help reinforce safety protocols and ensure your team is prepared for emergencies. Simulate different scenarios where safety protocols must be applied, such as chemical spills or equipment malfunctions.

Debrief and Review

After each training session or drill, conduct a debriefing to review safety practices. Discuss what went well and identify areas for improvement. Encourage your team to ask questions and provide feedback. Continuous review and reinforcement of safety protocols keep everyone vigilant and prepared.

Summary

Training on a Mobile Foam Unit is comprehensive, covering operation, maintenance, and safety protocols. By incorporating hands-on practice sessions and focusing on safety, you ensure your team is well-prepared and confident in their abilities. Regular training, continuous improvement, and a commitment to safety are the keys to effective and safe operation. Invest in your team’s training, and you’ll see the benefits in their performance and readiness during emergencies.

Frequently Asked Question on Maintenance of Mobile Foam Unit:

What are the essential training modules for a Mobile Foam Unit?

-

✓

- Essential training modules for a Mobile Foam Unit include understanding the basics, operating the unit, safety protocols, and troubleshooting and maintenance. These modules ensure that your team is well-prepared to use the equipment effectively during emergencies.

How do you operate a mobile foam unit effectively?

-

✓

- To operate a mobile foam unit, start by setting up the unit properly, ensuring all connections are secure. Follow detailed instructions for starting, operating, and stopping the unit safely. Regular practice and understanding of the equipment’s controls are crucial for effective operation.

What safety protocols should be followed when using an FRP Mobile Foam Unit?

-

✓

- Safety protocols include wearing appropriate personal protective equipment (PPE), conducting regular safety checks, handling foam agents properly, and knowing emergency shutdown procedures. Emphasizing safety helps prevent accidents and ensures efficient operation during emergencies.

What does training for mobile foam units in firefighting involve?

-

✓

- Training for mobile foam units in firefighting involves comprehensive instruction on the unit’s operation, maintenance, and safety protocols. It also includes hands-on practice sessions, simulating real-life firefighting scenarios to build confidence and competence. If you want to learn more on How to Operate Mobile Foam Unit, Click here.

What emergency procedures should be followed with foam units?

-

✓

- Emergency procedures include immediately shutting off the power source, disconnecting hoses safely, evacuating the area, and notifying supervisors or emergency services. Regular drills and reviews of these procedures ensure your team is prepared for any emergency situation.

What are some maintenance tips for mobile foam units?

-

✓

- Maintenance tips include conducting regular inspections for wear and tear, checking foam concentrate levels, cleaning the foam tank and hoses, and keeping a maintenance log. Proper maintenance ensures the unit operates smoothly and effectively during emergencies.

How can hands-on practice improve foam unit training?

-

✓

- Hands-on practice allows team members to gain real-world experience with the equipment, reinforcing their learning. Simulating real emergencies, practicing setup and operation, and troubleshooting common issues enhance their confidence and readiness.

What personal protective equipment (PPE) is required for foam unit operations?

-

✓

- Essential PPE includes helmets, gloves, flame-resistant clothing, safety goggles, and non-slip, steel-toed boots. Proper use of PPE protects team members from potential hazards during foam unit operations.

How can you simulate firefighting scenarios with foam units effectively?

-

✓

- Simulating firefighting scenarios involves creating mock situations with controlled fires, timed drills, and obstacle courses. These simulations test skills, build confidence, and prepare the team for real emergencies by mimicking chaotic conditions in a safe environment.

What are common troubleshooting steps for mobile foam units?

-

✓

- Common troubleshooting steps include checking foam concentrate levels, inspecting hoses for blockages, verifying pressure settings, and performing routine maintenance checks. Understanding how to diagnose and fix issues ensures the unit remains reliable and effective during use.