Mastering the Types of Valves in Fire Fighting Systems: A Comprehensive Guide

Understanding the Importance of Valves in Fire Suppression

Fire fighting systems are composed of many critical and important components, wherein valves play a critical role in controlling the flow of water or other extinguishing agents. These seemingly simple devices are an integral yet effective and reliable part of fire suppression systems.

For details on different types of firefighting system click here.

In this blog we shall be discussing the Gate and Butterfly valves used in the fire fighting system with its pros, cons and many other aspects.

In this comprehensive guide, we’ll delve into the importance of valves in fire suppression and explore real-world examples of their significance.

Design By Freepik

-

✓

Control and Regulation:

- Valves act as the gatekeepers of water or extinguishing agent flow within a fire fighting system.

- ✓ These types of valves enable firefighters or system operators to control the distribution and pressure of the extinguishing agent, ensuring optimal performance during fire emergencies.

- ✓ Without properly functioning valves, the effectiveness of the entire system can be compromised.

Isolation and Segmentation:

- ✓ Valves allow for the isolation and segmentation of different sections of a fire fighting system. This feature is crucial for containing fires to specific areas, preventing their spread to other parts of a building or facility.

- ✓ By closing valves in unaffected areas, firefighters can focus the flow of extinguishing agents precisely where they’re needed most.

Maintenance and Repair:

- ✓ Valves facilitate maintenance and repair activities within fire fighting systems. By shutting off the flow of water or extinguishing agents, valves allow technicians to safely conduct inspections, repairs, or upgrades without disrupting overall system functionality.

- ✓ Regular maintenance of valves ensures their reliability during emergencies.

Pressure Regulation and Safety:

- ✓ Valves play a crucial role in regulating pressure within fire fighting systems to prevent over-pressurization or under-pressurization.

- ✓ Proper pressure control ensures that extinguishing agents are delivered at the optimal flow rate and pressure, maximizing their effectiveness in suppressing fires while minimizing the risk of damage to system components or structural integrity.

It is to be noted that valves are indispensable components of fire fighting systems, playing a multifaceted role in controlling, isolating, maintaining, and regulating the flow of extinguishing agents.

Key Takeaway

Remember these important insights as you continue reading.

By understanding the importance of valves and their functions, fire safety professionals can ensure the reliability and effectiveness of fire suppression systems, ultimately safeguarding lives and property against the ravages of fire.

Stay tuned for the next sections of our comprehensive guide, where we’ll delve into the types of valves used in fire fighting systems and best practices for their installation, operation, and maintenance.

-

✓

Common Types of Valves Used in Fire Fighting Systems

Valves are the unsung heroes of fire fighting systems, regulating the flow of water or extinguishing agents to effectively combat fires. Understanding the different types of valves used in these systems is crucial for designing, installing, and maintaining effective fire suppression systems. In this comprehensive guide, we’ll explore the common types of valves utilized in fire fighting systems and their respective roles in ensuring fire safety.

-

✓

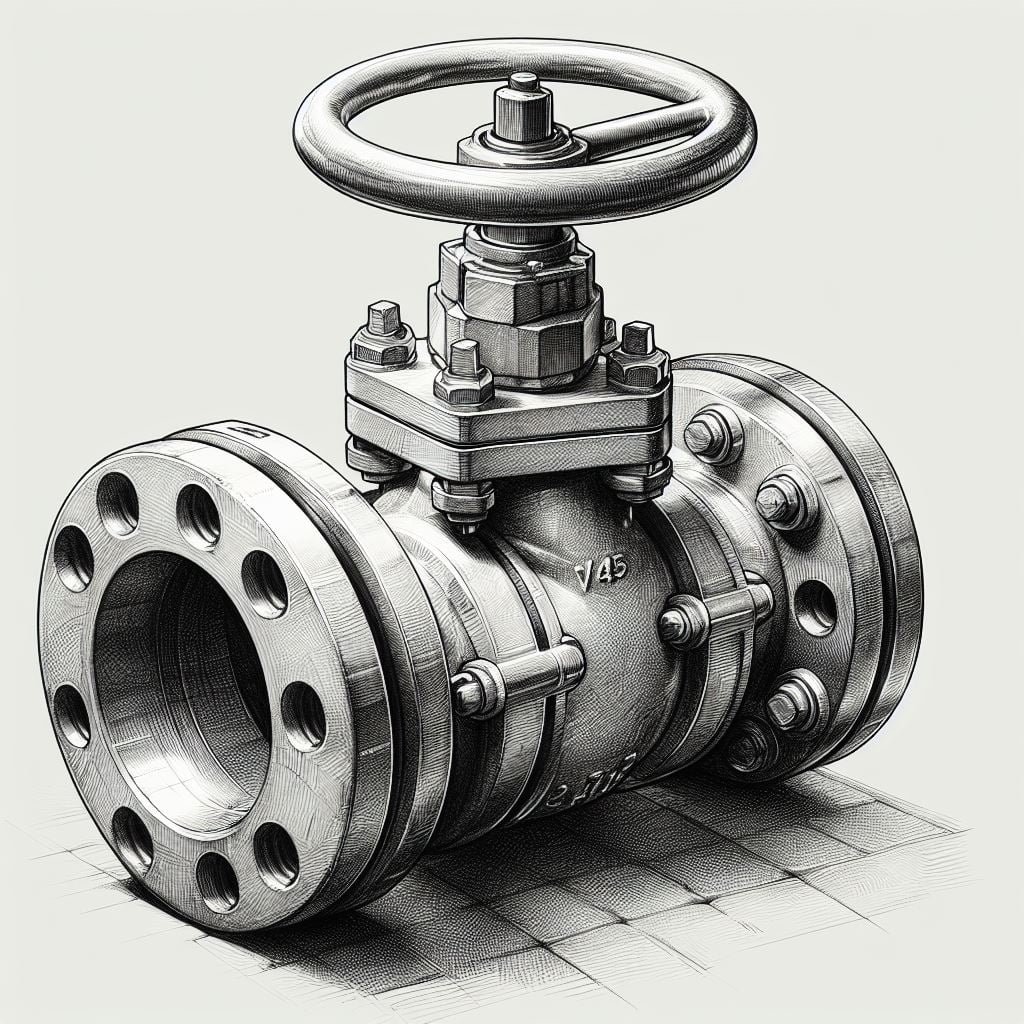

Gate Valves:

- Gate valves are one of the most commonly used types of valves in fire fighting systems. They feature a simple design consisting of a gate or wedge that moves up and down to control the flow of water.

- ✓ When fully open, gate valves allow unrestricted flow, making them ideal for quickly delivering large volumes of water to extinguish fires.

-

✓

These valves are typically found in main supply lines and hydrants, where rapid water delivery is essential during emergencies.

Butterfly Valves:

- ✓ Butterfly valves are another popular choice for fire fighting systems due to their compact design and efficient flow control capabilities.

- ✓ These valves feature a flat disc or “butterfly” that rotates within the valve body to regulate flow. Butterfly valves are well-suited for applications requiring moderate flow rates and are commonly used in sprinkler systems and standpipe systems.

- ✓ Their quick operation and low maintenance requirements make them an attractive option for fire protection.

Ball Valves:

- ✓ Ball valves are known for their durability and reliability in fire fighting applications. They consist of a spherical disc with a hole (the “ball”) that controls flow by rotating within the valve body.

- ✓ Ball valves provide excellent shut-off capabilities, making them ideal for isolating sections of a fire fighting system during maintenance or repairs.

- ✓ While they may be more expensive than other valve types, their long service life and minimal leakage make them a worthwhile investment.

-

✓

Check Valves:

- Check valves are essential components of fire fighting systems, ensuring that water flows in one direction only.

- ✓ These valves feature a hinged or spring-loaded disc that opens to allow flow in the desired direction and closes to prevent backflow.

- ✓ Check valves are commonly installed in fire pump discharge lines and standpipe systems to prevent water from flowing back into the system once it has been discharged.

- ✓ Their reliable operation helps maintain system integrity and prevent contamination of water sources.

Pressure Reducing Valves (PRVs):

- ✓ Pressure reducing valves play a critical role in maintaining consistent water pressure within fire fighting systems.

- ✓ These valves automatically adjust the incoming water pressure to a predetermined level, ensuring that sprinkler heads and other fire suppression devices operate effectively.

- ✓ PRVs are typically installed at the inlet of fire suppression systems or at strategic points along supply lines to regulate pressure and prevent damage to system components.

-

✓

Alarm Check Valves:

- Alarm check valves are specialized valves designed to activate alarm systems when water flows through them. These valves feature a clapper mechanism that opens to allow water flow during a fire emergency.

- ✓ When water flows through the valve, it triggers a pressure switch or alarm device, alerting building occupants and emergency responders to the presence of a fire.

- ✓ Alarm check valves are commonly used in sprinkler systems and standpipe systems to provide early warning of fire events.

-

✓

Why is it important to select the right type of valves for a fire fighting system?

The selection and installation of the right types of valves are crucial for the effectiveness and reliability of fire fighting systems. By understanding the roles and characteristics of common valve types, fire safety professionals can design robust fire suppression systems capable of protecting lives and property in the event of a fire emergency. In the next section of our comprehensive guide, we’ll delve into best practices for the installation, operation, and maintenance of valves in fire fighting systems. Stay tuned for more insights into optimizing fire safety through effective valve management.

Key Takeaway

Remember these important insights as you continue reading.

-

✓

Functions and Operations of Gate Valves & Butterfly Valves in Fire Suppression:

Gate valves and butterfly valves are two common types of valves used in fire fighting systems, each with its own unique characteristics and applications. Understanding the functionality and operation of these valves is essential for designing effective fire suppression systems. In this section of our comprehensive guide, we’ll explore the key aspects of gate valves and butterfly valves, including their functionality, operation, and major differences.

-

✓

Functionality

- Gate Valves: Gate valves control the flow of fluid through a pipe by raising or lowering a gate or wedge mechanism. When fully open, the gate is lifted clear of the flow path, allowing unobstructed flow. When closed, the gate creates a seal to prevent the flow of fluid. Gate valves provide a tight seal when fully closed, effectively isolating sections of a firefighting system.

- ✓ Butterfly Valves: Butterfly valves control flow using a disc that rotates within the valve body. When the valve is fully open, the disc is turned parallel to the flow direction, allowing unobstructed flow. When closed, the disc is turned perpendicular to the flow, creating a seal to prevent the flow of fluid. Butterfly valves provide quick shutoff and are often used in applications requiring rapid response times.

Operation

- ✓ Gate Valves: Gate valves can be operated manually or automatically. In manual gate valves, a hand wheel or lever is used to rotate the stem, raising or lowering the gate to control flow. In automatic gate valves, an actuator or motor automates the valve operation, allowing for remote control or integration with fire detection and alarm systems. Gate valves provide on-the-spot control of water distribution during fire emergencies.

- ✓ Butterfly Valves: Butterfly valves are typically operated manually using a hand lever or gear mechanism to rotate the disc within the valve body. Some butterfly valves may also be operated using pneumatic or electric actuators for remote control. Butterfly valves offer quick and easy operation, making them suitable for applications requiring rapid response times.

Major Applications

- ✓ Gate Valves: Gate valves are commonly used in main supply lines, hydrants, and branch lines in firefighting systems where precise control of water flow is essential. They are also used in industrial settings, water treatment plants, and oil and gas pipelines.

- ✓ Butterfly Valves: Butterfly valves are often used in fire protection systems, HVAC systems, and water treatment plants. They are well-suited for applications requiring quick shutoff and minimal pressure drop.

Advantages and Disadvantages

-

✓

Gate Valves:

- Advantages:

- Provide a tight seal when fully closed.

- ✓ Allow for precise control of water flow.

- ✓ Suitable for high-pressure applications.

- ✓ Can be operated manually or automatically.

- Disadvantages:

- ✓ Slower operation compared to butterfly valves.

- ✓ Prone to wear and corrosion over time.

- ✓ Require more maintenance.

- ✓ May experience leakage if not properly maintained.

- Advantages:

- Butterfly Valves:

-

✓

Advantages:

- Quick and easy to operate.

- ✓ Offer minimal pressure drop.

- ✓ Compact design requires less space for installation.

- ✓ Suitable for applications requiring rapid response times.

- Disadvantages:

- ✓ Not suitable for high-pressure applications.

- ✓ Limited in size compared to gate valves.

- ✓ May experience wear and tear over time, affecting sealing performance.

- ✓ Require periodic maintenance to ensure proper operation.

-

✓

Advantages:

-

✓

Gate Valves:

Major Differences between Gate Valves and Butterfly Valves:

It can be concluded that both gate valves and butterfly valves play crucial roles in fire fighting systems, offering unique advantages and applications. While gate valves provide precise control and are suitable for high-pressure applications, butterfly valves offer quick operation and minimal pressure drop. Understanding the differences between these valves is essential for selecting the right type for specific fire suppression needs. Stay tuned for the final section of our comprehensive guide, where we’ll explore best practices for the installation, maintenance, and inspection of valves in fire fighting systems.

Key Takeaway

Remember these important insights as you continue reading.

-

✓

Functionality

- Gate Valves: Gate valves control the flow of fluid through a pipe by raising or lowering a gate or wedge mechanism. When fully open, the gate is lifted clear of the flow path, allowing unobstructed flow. When closed, the gate creates a seal to prevent the flow of fluid. Gate valves provide a tight seal when fully closed, effectively isolating sections of a fire fighting system.

- ✓ Butterfly Valves: Butterfly valves control flow using a disc that rotates within the valve body. When the valve is fully open, the disc is turned parallel to the flow direction, allowing unobstructed flow. When closed, the disc is turned perpendicular to the flow, creating a seal to prevent the flow of fluid. Butterfly valves provide quick shutoff and are often used in applications requiring rapid response times.

Operation

- ✓ Gate Valves: Gate valves can be operated manually or automatically. In manual gate valves, a hand wheel or lever is used to rotate the stem, raising or lowering the gate to control flow. In automatic gate valves, an actuator or motor automates the valve operation, allowing for remote control or integration with fire detection and alarm systems. Gate valves provide on-the-spot control of water distribution during fire emergencies.

- ✓ Butterfly Valves: Butterfly valves are typically operated manually using a hand lever or gear mechanism to rotate the disc within the valve body. Some butterfly valves may also be operated using pneumatic or electric actuators for remote control. Butterfly valves offer quick and easy operation, making them suitable for applications requiring rapid response times.

Major Applications

- ✓ Gate Valves: Gate valves are commonly used in main supply lines, hydrants, and branch lines in fire fighting systems where precise control of water flow is essential. They are also used in industrial settings, water treatment plants, and oil and gas pipelines.

- ✓ Butterfly Valves: Butterfly valves are often used in fire protection systems, HVAC systems, and water treatment plants. They are well-suited for applications requiring quick shutoff and minimal pressure drop.

Pros and Cons

-

✓

Gate Valves:

- Pros:

- Provide a tight seal when fully closed

- ✓ Allow for precise control of water flow

- ✓ Suitable for high-pressure applications

- ✓ Can be operated manually or automatically

- Cons:

- ✓ Slower operation compared to butterfly valves

- ✓ Prone to wear and corrosion over time

- ✓ Require more maintenance

- ✓ May experience leakage if not properly maintained

- Pros:

- Butterfly Valves:

-

✓

Pros:

- Quick and easy to operate

- ✓ Offer minimal pressure drop

- ✓ Compact design requires less space for installation

- ✓ Suitable for applications requiring rapid response times

- Cons:

- ✓ Not suitable for high-pressure applications

- ✓ Limited in size compared to gate valves

- ✓ May experience wear and tear over time, affecting sealing performance

- ✓ Require periodic maintenance to ensure proper operation

-

✓

Pros:

-

✓

Gate Valves:

Understanding the differences between gate valves and butterfly valves, including their functionality, operation, applications, pros, and cons, can help in selecting the right valve for your specific needs.

Key Takeaway

Remember these important insights as you continue reading.

Applications and Advantages of Gate Valves & Butterfly Valves in Fire Protection

-

✓

- Applications

- Gate Valves:

- Main Supply Lines: Gate valves are commonly used to control the flow of water from the main water source to various sections of a fire protection system.

- ✓ Hydrants: Gate valves are installed at hydrants to control the flow of water for firefighting operations.

- ✓ Branch Lines: Gate valves are utilized in branch lines to direct water to specific areas or sections of a building during fire emergencies.

- Butterfly Valves:

- ✓ HVAC Systems: Butterfly valves are often employed in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of air or water for fire protection purposes.

- ✓ Water Treatment Plants: Butterfly valves play a vital role in water treatment plants, where they regulate the flow of water for fire protection and other processes.

- ✓ Fire Protection Systems: Butterfly valves are integral components of fire protection systems, controlling the flow of water or extinguishing agents to suppress fires.

- Gate Valves:

- Advantages

-

✓

Gate Valves:

- Precise Control: Gate valves offer precise control over the flow of water, allowing firefighters to regulate water distribution during fire suppression operations.

- ✓ High Pressure Capability: Gate valves are suitable for high-pressure applications, making them ideal for controlling water flow in fire protection systems.

- ✓ Reliability: Gate valves provide a tight seal when fully closed, minimizing the risk of water leakage and ensuring reliable performance during fire emergencies.

- ✓ Versatility: Gate valves can be operated manually or automatically, providing flexibility in controlling water flow based on specific requirements or conditions.

- Butterfly Valves:

- ✓ Quick Operation: Butterfly valves can be operated swiftly, providing rapid response times in emergency situations.

- ✓ Minimal Pressure Drop: Butterfly valves offer minimal pressure drop, ensuring efficient water flow during fire suppression activities.

- ✓ Compact Design: Butterfly valves feature a compact design, requiring less space for installation and maintenance.

- ✓ Ease of Installation: Butterfly valves are relatively easy to install and maintain, reducing downtime and costs associated with system maintenance.

-

✓

Gate Valves:

- Applications

Gate valves and butterfly valves are critical components of fire fighting systems, each offering unique applications and advantages in safeguarding lives and property against the threat of fire. Understanding the specific roles and benefits of these valves is essential for designing effective fire protection systems. In this section of our comprehensive guide, we’ll explore the applications and advantages of gate valves and butterfly valves in fire protection, presented in a tabular format for easy comprehension.

Key Takeaway

Remember these important insights as you continue reading.

In summary, gate valves and butterfly valves play vital roles in fire protection systems, offering distinct advantages in controlling the flow of water or extinguishing agents during fire emergencies. While gate valves provide precise control and reliability, butterfly valves offer quick operation and minimal pressure drop. Understanding the applications and benefits of these valves is essential for designing effective fire protection systems that can effectively suppress fires and protect lives and property. Stay tuned for more insights into optimizing fire safety through effective valve management and system design.

Checklist to select Gate Valves or Butterfly valves for fire suppression system:

- ✓ Determine the required flow rate and pressure for the fire protection system:

-

✓

- Low, Medium,

-

✓

- High Specific Flow Rate (e.g., gallons per minute),

-

✓

- Pressure Ratings (e.g., PSI)

- ✓ Consider the size and location of the installation to determine space constraints:

-

✓

- Small, Medium, Large

-

✓

- Indoor, Outdoor

-

✓

- Confined Spaces

- ✓ Evaluate the operating environment for potential exposure to corrosive materials or extreme temperatures:

-

✓

- Corrosive Environment (e.g., chemicals, saltwater)

-

✓

- High Temperature

-

✓

- Low Temperature

- ✓ Assess the compatibility of materials with the fluid being transported (e.g., water, foam, chemical agents):

-

✓

- Water

-

✓

- Foam

-

✓

- Chemical Agents

- ✓ Determine the need for manual or automatic valve operation based on system requirements:

-

✓

- Manual

-

✓

- Automatic

-

✓

- Both (Manual Override for Automatic)

- ✓ Evaluate the reliability and sealing capability of the valve to prevent leakage during fire emergencies:

-

✓

- Tight Sealing

-

✓

- Leakage Prevention

-

✓

- High Reliability

- ✓ Consider the ease of installation and maintenance to minimize downtime and associated costs:

-

✓

- Easy Installation

-

✓

- Low Maintenance

-

✓

- Quick Access for Maintenance

- ✓ Assess the valve’s response time and ability to provide rapid shutoff during fire events:

-

✓

- Quick Response Time

-

✓

- Rapid Shutoff

-

✓

- High Flow Control

- ✓ Ensure compliance with relevant industry standards and regulations for fire protection systems:

-

✓

- NFPA Standards

-

✓

- UL Listed

-

✓

- FM Approved

- ✓ Compare the cost-effectiveness of gate valves and butterfly valves based on performance and longevity:

-

✓

- Cost-Effective Option

-

✓

- Longevity and Durability

-

✓

- Value for Money

-

✓

Frequently Asked question on Gate Valves, Butterfly valves & Fire Suppression System:

-

1

What is the role of valves in fire fighting systems?

- ✓ Valves control the flow of water or extinguishing agents in fire suppression systems, allowing firefighters to regulate the distribution of resources during emergencies.

-

2

What types of valves are commonly used in fire fighting systems?

- ✓ Common types of valves include gate valves, butterfly valves, ball valves, check valves, and pressure reducing valves.

-

3

How do gate valves differ from butterfly valves in fire protection applications?

- ✓ Gate valves control flow using a gate or wedge mechanism, while butterfly valves use a disc that rotates within the valve body. Gate valves provide precise control and high pressure capability, while butterfly valves offer quick operation and minimal pressure drop.

-

4

What are the key factors to consider when selecting valves for fire protection systems?

- ✓ Factors include flow rate, pressure requirements, space constraints, material compatibility, operating environment, reliability, ease of installation and maintenance, response time, compliance with standards, and cost-effectiveness.

-

5

How can valves contribute to the effectiveness of fire suppression systems?

- ✓ Valves allow firefighters to control the flow of water or extinguishing agents, directing resources to areas where they are needed most to suppress fires and protect life and property.

-

6

What maintenance procedures are required for valves in fire fighting systems?

- ✓ Maintenance procedures may include regular inspection, lubrication, testing, and replacement of worn components to ensure proper operation and reliability during emergencies.

-

7

Are there specific standards and regulations that govern the installation and operation of valves in fire protection systems?

- ✓ Yes, valves in fire protection systems must comply with industry standards such as those set by the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL).

-

8

What are some common issues or challenges encountered with valves in fire fighting systems?

- ✓ Common issues include leakage, corrosion, obstruction, malfunctioning actuators, and inadequate flow control, which can compromise the effectiveness of fire suppression systems.

-

9

How can valves be integrated with other components of fire fighting systems for optimal performance?

- ✓ Valves can be integrated with pumps, hoses, nozzles, sprinkler heads, control panels, and alarm systems to create a comprehensive fire protection infrastructure.

-

10

What are some best practices for ensuring the reliability and longevity of valves in fire fighting systems?

-

✓

Best practices include regular inspection and maintenance, proper installation, use of high-quality materials, adherence to manufacturer recommendations, and training personnel in valve operation and maintenance procedures.

If you need to know about various types of fire classes then Click here.

-

✓

Best practices include regular inspection and maintenance, proper installation, use of high-quality materials, adherence to manufacturer recommendations, and training personnel in valve operation and maintenance procedures.